AS-568 O-Ring Guide | JIS O-Ring Guide

O-Rings are solid-rubber, doughnut-shaped seals used to block the passage of a gas or liquid when pressed between two mating surfaces.

They are amongst the most widely utilized seal designs in the world. Due to the number of ways they can be utilized, there are essentially an endless number of O-Ring sizes.

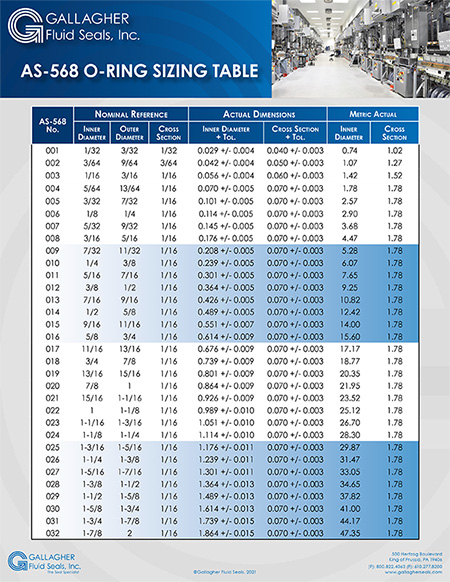

But despite the wide range of O-Ring sizes, every O-Ring has the same two dimensions: the inner diameter (ID), and the cross-section (CS). To attain an adequate seal, it must achieve proper compression, approximately 18-20% in the cross sectional characteristic. This creates a boundary to keep fluids in and contaminants out.

The wide ranges of ID dimensions of O-Rings are developed around standard inch fractional sizes. This sizing system is referred to as the AS-568 sizing standard. For those looking for Japanese Standard sizes (JIS), download the JIS o-ring sizing guide here. There is also standard Metric sizing system and DIN sizing system. This accommodates standard industrial hardware shaft and bore sizes.

Levels of Inner Diameter stretch for O-Rings are application dependent.

Another factor related to O-Ring size is cross section. Proper cross section design depends on the size of the gland. To ensure the proper amount of squeeze needed for an adequate seal, the O-Ring cross section needs to be larger than the height of the gland.

The “diametrical clearance” is the gap between the two mating hardware surfaces, also known as the extrusion gap. The O-Ring squeeze focuses on the extrusion gap and seals.

There are crucial differences when identifying the size of an O-Ring cross section depending on whether the application is static or dynamic. With a dynamic application, a smaller cross section is needed.

Gallagher Fluid Seals provides o-rings to a wide variety of industries, and is partnered with the world's top suppliers. GFS carries NBR, Silicone, FFKM, FKM, PTFE, EPDM, VMQ, Neoprene, and more.

If you're looking to learn more about O-Ring technical performance characteristics, materials, chemical and temperature compatibility, hardware considerations and failure modes... download our definitive o-ring design guide.

Or, watch our introduction to o-rings youtube video below:

For custom o-ring projects, Contact our engineering department.

For non-standard o-ring sizes, check out the Parker 5-Dash Series on our website.