INDUSTRY

Chemical

CUSTOMER

Large Petrochemical Plant

CUSTOMER BACKGROUND

The customer is a maker of petrochemical feed-stocks used in the manufacture of plastics, rubber, fibers, solvents, detergents, fertilizers and paints.

CHALLENGES FACED BY CUSTOMER

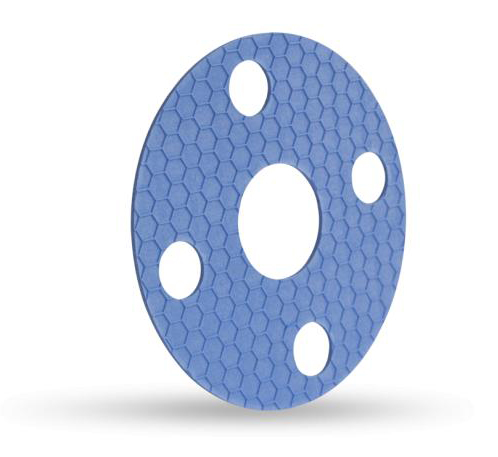

The customer had been using a silica filled PTFE, 2mm thick sheet gasket material. However, old and uneven flanges created leakage issues that the plant wanted to eliminate.

Flange sizes ranged from 25mm to 500mm (1” to 20”). The customer was open to trying new gasket technology to get rid of leaks in old and uneven flange connections.

OPERATING CONDITIONS AT PLANT

- Temperature: 86°F (30°C) to 194°F (90°C)

- Application: Stainless steel PN 25 flanges on a nitrogen monoxide compressor and a nitric acid in tank farm pipe system

- Media: Nitrogen Monoxide and Nitric acid 68%

- Pressure: 25 bar-g (363 psig) maximum

- Size:100mm (4”) for first trials

SOLUTION AND BENEFITS

GYLON EPIX® 3501 installations began in October of 2018. All installations are still sealing well and new installations are continually added. Gasket sizes are being installed in pipe size ranging from DN25 (NPS 1”) to DN500 (NPS 20”). The plant personnel consider GYLON EPIX® a problem solver for old and uneven flanges.

The original article and case study can be found on Garlock's website here.

Gallgaher Fluid Seals is an authorized distributor for Garlock products. For more information about this application, contact Gallagher Fluid Seals today.