Jigsaw Seals: Versatile Sealing Solutions for Low Production Joints

Innovative Cut-To-Length Sealing

Sealing large joints or multiple grooves can pose cost and timing issues within product development. Extruded cord is often used to work within the program budgets and time constraints. However, that can create issues with splicing, RTV application, and inventory management.

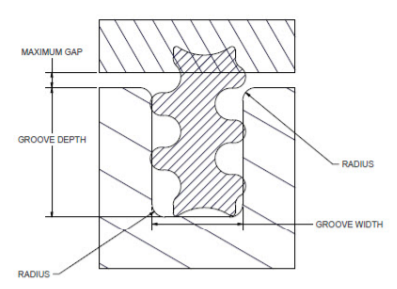

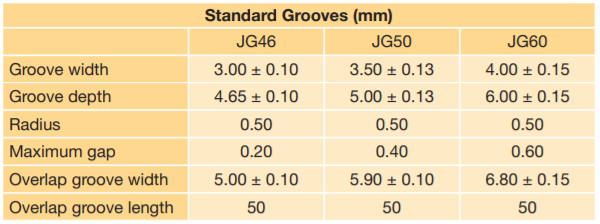

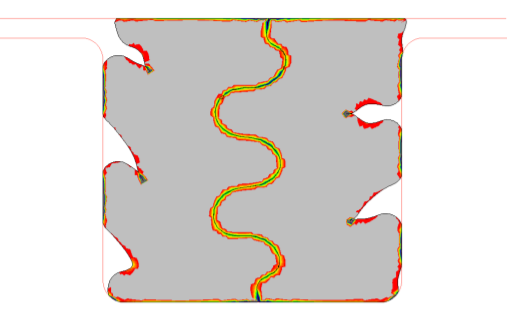

To address these challenges, Parker has developed a new “Jigsaw” extruded seal design. The differentiating feature of this unique cross-section is the precise interlock when the cut-to-length seal ends are overlapped. When compressed, this patent pending interlock seals against itself and creates an RTV free joint.

Parker’s Jigsaw seal is typically supplied coiled on spools, so it can be used in paths of all different lengths. This elegant sealing solution reduces up front costs and provides easy seal installation. As a bonus, the seal is self-retaining to facilitate inverted assembly operations or transportation prior to final assembly.

For more information about Parker Jigsaw Extruded Seals, contact Gallagher Fluid Seals today.

Gallagher is an authorized distributor for Parker Hannifin Seals. The original article can be found on Parker's website here.