The limited bolting resulted in inadequate compression to seal the gasket and the non-standard shape made the use of a molded engineered gasket unfeasible. When tested, expanded PTFE leaked. There was no alternative known at that time so the mess of crystalized leaking media was accepted as normal.

OPERATING CONDITIONS AT CUSTOMER FACILITY

- Temperature – 86°F (30°C) - 104°F (40°C)

- Application – Custom rectangular flange

- Media – Dilute Caustic Soda

- Pressure – 50 psig (3.5 bar-g)

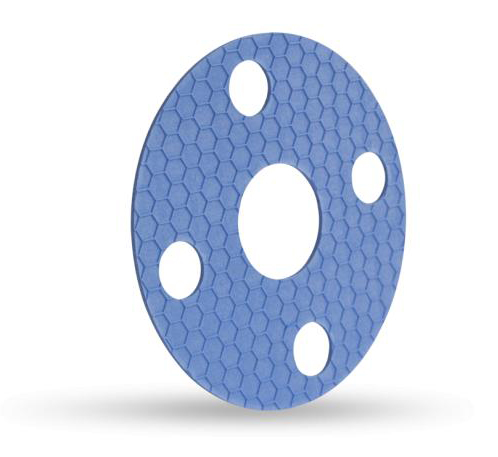

SOLUTION AND BENEFITS OF GYLON EPIX 3504

GYLON EPIX® 3504 was installed successfully and was running efficiently with no leaks after an 18-month checkup. The raised features of GYLON EPIX® and its availability in sheet form overcame the problems of limited bolting and the rectangular custom shape. GYLON EPIX® also helped eliminate caustic crystal build up.

The original article was written by Garlock and can be found on their website here.

For more information about GYLON gaskets, or engineered profiles of gaskets, contact Gallagher Fluid Seals today.