If you want to drastically improve the efficiency of your pump and reduce maintenance, the first thing to do is change your approach to maintaining your pump. Focus not just on the specialized equipment your plant uses, but focus on valves, pipes, and other crucial operational equipment.

Did you know that the most common source of wasted energy in pumping systems has to do with seals that weren’t properly sized for their applications? This causes throttling of the pump’s flow, and reduces efficiency. Pumps that operate in this manner also produce higher levels of vibration, which will cause unnecessary damage and reduce the longevity of the seals.

Where Does Mechanical Seal Failure Begin?

While improvements in mechanical seal design have drastically improved their lifespan, using seals outside of their intended environment will cause them to fall short. Much of the time, the problem is that the pump has been used outside of its desired application range. By taking the time to ensure that the entire system is working properly, and fixing problems at their source, you may be able to obtain the best efficiency point (BES) and extend the life of your seals.

Root Causes

If a premature mechanical seal failure occurs, there are several common root causes which should be investigated to reach optimal performance for the whole system. In most cases, sealing devices are being used in an off-design operation. This can cause excess vibrations transmitted throughout the pump, and damages the seals installed in the system.

Avoid these root causes of mechanical seal failure

- Excessive vibration in the seal chamber cavitation, internal re-circulation, or asymmetrical wear

- Cavitation refers to the vaporization of the fluid and fluid film in the seal chamber

- Temperature increases in the seal chamber under low-flow conditions will cause vaporization of the fluid in the seal chamber

- Insufficient cooling flow from mechanical seal support system

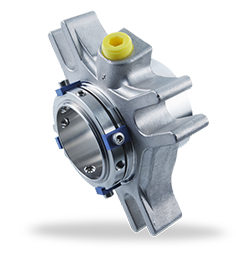

Critical Seal Components

The mating pair of seal rings is the most sensitive to vibration and insufficient lubrication. Choose these rings carefully based on the conditions of the sealed environment, including the temperature and surface pressures involved. These conditions can change quickly when the seal is exposed to vibration or lacks the sufficient lubrication. Sealing systems try to compensate for changing interface conditions, but off design pump operations may damage the seal if it is forced into a setting it was not intended for. Be wary of more subtle damage which may result from leakage at the seal interface. The cause of this may be unrelated to the material of the seal or its design.

Through taking a more holistic, involved approach in the subsystems of your pump, it can help save money on seal maintenance and improve overall efficiency.

If you are having mechanical seal repair issues, or need refurbishment, contact Gallagher Fluid Seals today.

Gallagher Fluid Seals is an authorized distributor for EagleBurgmann mechanical seals.

The original article can be found here.