Falk Gearbox

It’s no secret that Falk gearbox parts have powered some of the world’s largest machinery for more than a century. But what most folks don’t realize is that the manufacturer’s legacy was built upon a river of beer.

That’s right. Before the Falk

From Wisconsin beer to Oregon gearboxes, products bearing the Falk name tend to rise to the top. So it’s no surprise that Franz’s Bavaria Brewery, founded in 1856, was a hit despite the stiff competition. With a 200,000-barrel production capacity (rivaling even some of today’s major breweries), the Falk family brewery outpaced both Schlitz and Miller combined during its peak years.

When a Fourth of July fire destroyed part of the brewery in 1889, so much beer spewed out into the Menomonee Valley you could stand in it up to your ankles.

Franz had passed away by that time,

From Beers to Falk Gears

Herman Falk, the fifth of Franz’s seven sons, wasn’t a big fan of brewing. He was more mechanically inclined.

An inventor and entrepreneur, he acquired his first patent at the age of 20, for “new and useful improvements in wagon-breaks.” By 1892, he had started a business making couplings for wagons. Today, Falk gear couplings are considered the industry gold standard. Back then, however, wagon couplings weren’t enough to sustain a business.

Fortunately, the money from the sale of the family brewery allowed him to expand. He soon opened a general-purpose machine shop in an old blacksmith building, where he built stage machinery for the Pabst Theater when he wasn’t working on wagons. Before long, a new technology caught his attention: electrified transportation. He invented a breakthrough process for manufacturing the joints between streetcar rails, and by 1900 nearly a third of the nation’s rail street rail tracks had Falk castings.

By that time, Falk had moved on to power transmission. As factories transitioned from steam power to electric motors, gears were needed to convert their superfluous speed into torque for driving conveyor belts and machine tools. Falk’s newly built 70,000-square-foot factory began pumping out gears and pinions in response.

But Falk wasn’t satisfied with producing ordinary spur gears for streetcars. He had heard of a Swiss machine that could produce precision herringbone gears. He bought the U.S. rights and debuted his new gears in 1911.

“Herman’s decision to enter the precision gearing field was undoubtedly the pivotal event in the company’s history,” says Milwaukee historian John Gurda.

Gearing Up for Success

It wasn’t long before Falk was producing heavy industrial gears for oceangoing vessels—including U.S. naval ships. He even made the gears that open and close the giant mechanical gates of the 51-mile-long Panama Canal, according to the Milwaukee County Historical Society.

The company has since manufactured more than 1,200 reverse reduction drives for tugboats and towboats as well as more than 1,800 special reduction gears for cruise ships, aircraft carriers and other marine vessels.

Today, Falk gearbox parts can be found in any number of industries, from paper to mining to cement. Its standard product lines include gear drives, Falk gear couplings and low-speed backstops.

Just as his dad helped make Milwaukee the beer capital of the world, Herman Falk helped make it a global center for manufacturing, earning the city a new title: “machine shop of the world.” Both helped make the Falk name synonymous with quality.

Original article can be found on Mar-Dustrial Sales's website.

Problems with your Falk Gearbox?

Traditional sealing methods for the flooded shafts are inadequate resulting in oil leaking out of the gearbox creating an environmental and safety hazard.

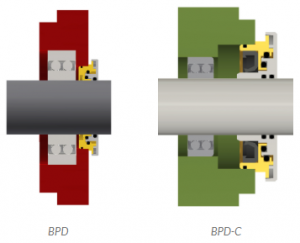

Solution: The BPD-C from Orion Engineered Seals

- Incorporates all of the contamination exclusion features of the standard BPD

- Designed specifically for flooded gearbox shafts.

- Contains oil in vertical down as well as horizontal positions

- Does not damage shaft

- Provides an operating environment in which the contacting component of the seal to works effectively for years

Gallagher Fluid seals is a preferred distributor of Orion Engineered Seals.

If you have questions about challenges you are facing in your plant, contact the Gallagher engineering department.