In a world where we are bombarded with the belief that “more is better”, sealing science contradicts that theory with facts that show “thinner is better” when it comes to gaskets, as they provide improved load retention, pressure resistance and sealability. Yet thicker gaskets have their place for uneven, worn or damaged sealing surfaces. So how does a person make the right choice? What if there was a product that could do both?

Now there is...

GYLON EPIX™ is a family of gaskets that effectively seals a broader range of applications and is more forgiving during the installation process. GYLON EPIX™ allows the end user to save valuable turnaround time, reduce re-work, and lower costs, helping them to finish ahead of schedule and under budget.

The innovative GYLON EPIX™, provides superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets used in worn and pitted flanges. In addition, GYLON EPIX™ delivers the sealing and load retention properties of 1/16” and the conformability of 1/8”. The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

The innovative GYLON EPIX™, provides superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets used in worn and pitted flanges. In addition, GYLON EPIX™ delivers the sealing and load retention properties of 1/16” and the conformability of 1/8”. The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

Inventory Simplification

Offered in one universal thickness, 3/32” (2.4mm), eliminating the need to stock a variety of material thicknesses with different stress requirements. This translates to reduced inventory and better sheet utilization.

Improved Load Retention

GYLON EPIX™ features a hexagonal surface profile that provides the torque retention and blowout resistance of a thin gasket and the conformability of a thicker gasket.

Trusted Materials

Made from the same PTFE material as standard GYLON® products it eliminates the need for most customers to qualify the new GYLON EPIX™ products.

The Next Generation in PTFE Gasketing

People or machines sitting idle results in products not being made, which affects your bottom line. Garlock is dedicated to helping our users minimize downtime and increase operational efficiency. The right combination of people, processes and technology align to optimize your business performance.

Industry Challenges

Industry Challenges

- Conflicting goals

- Understaffing

- Under trained maintenance personnel

- Outsourced / temporary labor

Reliability engineers are now responsible for a lot more equipment or areas of the plant than in the past.

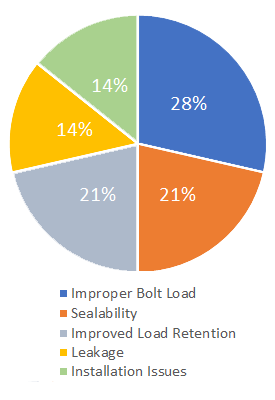

Common Gasketing Challenges

Improper Bolt Load

Improper Bolt Load

End-users struggle when it comes to ensuring gaskets are installed to proper bolt loads, as gaskets require different loads.

Sealability

End-users want a gasket that seals tighter. When available assembly stresses are less than ideal.

Improved Load Retention

End-users struggle with gaskets that leak prematurely due to load loss and need gaskets with improved load retention for better service life.

Leakage

End-users are frustrated by gaskets that leak, particularly when carrying aggressive and/or corrosive materials

Installation Issues

End-users are frustrated when equipment damage and unplanned outages happen due to human error and installation mistakes.

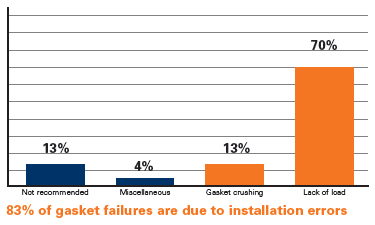

83% of gasket failures are due to installation errors. GYLON EPIX™ can solve all your gasketing installation problems with its improved load retention, pressure resistance, and sealability. Available in Style 3500 EPX, Style 3504 EPX, and Style 3510 EPX. If you have any questions about GYLON EPIX™, please don't hesitate to contact the Gallagher Engineering team.

83% of gasket failures are due to installation errors. GYLON EPIX™ can solve all your gasketing installation problems with its improved load retention, pressure resistance, and sealability. Available in Style 3500 EPX, Style 3504 EPX, and Style 3510 EPX. If you have any questions about GYLON EPIX™, please don't hesitate to contact the Gallagher Engineering team.