Our partner at Eclipse was approached by a valve component manufacturer for a sealing solution for a heavy-lift expendable launch vehicle.

The valve was used in the Hydrogen fuel side of advanced rocket boosters. These boosters are designed to carry the next generation of both cargo and manned exploration vehicles into deep space.

With ever increasing payload requirements and intensive cost sensitivity, rocket booster design and technology has been advanced to meet the demands and requirements.

Sealing Requirements:

- Media: GH2

- Pressure, Operating/Proof/Burst: 4,750/6,500/12,500 PSIG

- Life Cycles: 10,000

- Operating Temperature Range: -200 to +200°F

While Eclipse’s Spring Energized Seals regularly perform under these operating conditions, the extremely stringent leakage requirement needed by the customer presented with a unique challenge.

Normally such tight leakage constraints are achieved with the use of very soft and compliant seal materials such as specialized O-rings or Thermoplastic Elastomers.

But the wide, extreme temperature range and friction requirements of the valve meant the use of soft, high sealabilty materials would not be possible.

It was known the application parameters meant using a PTFE based seal material would be required. A typical, standard PTFE spring energized seal would not meet the customer’s leakage requirement.

Attention was turned to surface interaction between the seal lip and hardware surface.

The Solution

If the seal lip and hardware surface finish could be optimized to exceedingly high levels, then the permeability of the Hydrogen between the mating interfaces could be greatly reduced.

Superfinishing has been a technique used on metals for many years. But methods used for metals don’t typically translate or work well for polymers.

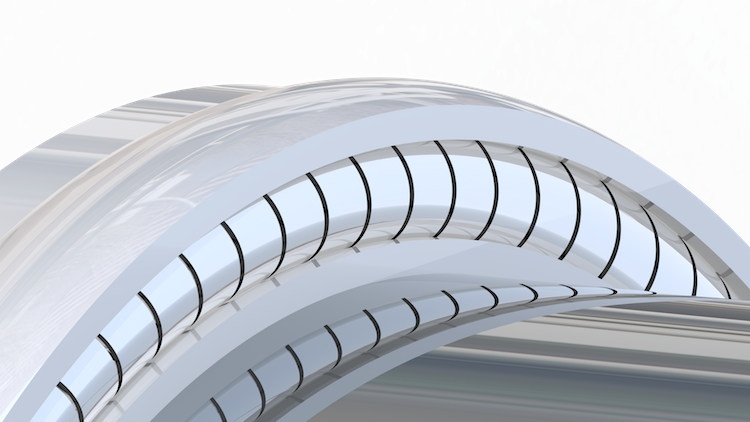

Eclipse’s in-house manufacturing and design team developed both special tooling and techniques to provide a similar superfinish on PTFE based seal materials.

In this case, to further improve sealability performance, EZ030 modified PTFE was used.

How it Performed

EZ030’s higher molecular structure density (when compared to standard PTFE) both improved gas permeability resistance and allowed for an exceptional surface finish.

The effort in developing the superfinish technique combined with the excellent properties of EZ030 resulted in a seal that met both the customer’s tough leakage requirement and life cycle targets.

The original article can be found on Eclipse Engineering's website here.

For more information about superfinishing techniques, contact Gallagher Fluid Seals today.