Garlock Gylon Gasketing Materials

When PTFE (polytetrafluorethylene) was developed in 1938, its importance to industrial sealing was quickly recognized because of its tremendous chemical resistance.

While use of PTFE as a gasket material increased in industrial applications, complaints about certain properties surfaced: skive marks made initial sealing difficult, cold flow caused leakage and premature failure, and temperature/pressure cycling was a problem.

Resistance to Cold Flow (Creep)

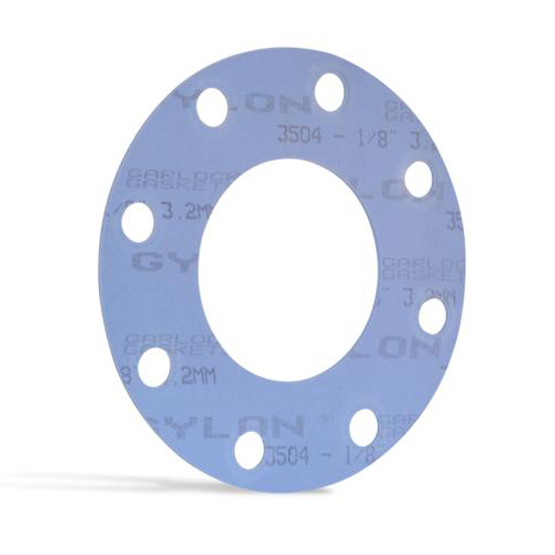

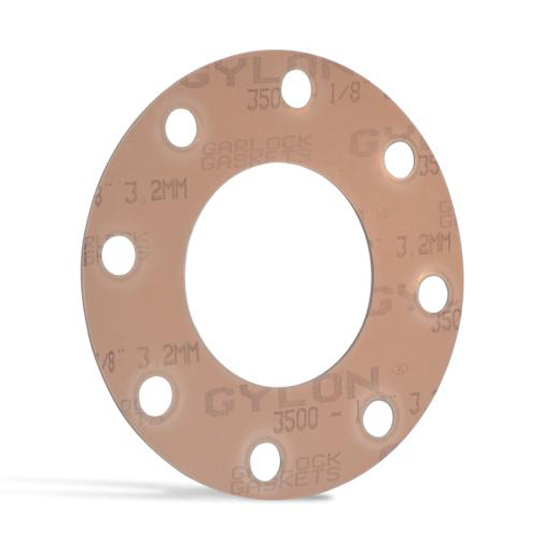

These drawbacks were eliminated when Garlock introduced Fawn GYLON®, Style 3500, in 1967. The GYLON process minimizes creep and cold flow normally associated with PTFE products, while retaining other positive characteristics of PTFE. Fawn GYLON® was so innovative that it received Chemical Processing magazine’s Vaaler Award in 1968. As the variety and quantity of industrial chemicals increased, Garlock realized that new products would be required to serve the growing market. Two additional GYLON styles were introduced to meet those demands: Blue GYLON, Style 3504, and Off-White GYLON, Style 3510.

Compressibility

As the diversity of applications grew, so did the types of piping systems. A large number of exotic piping systems were required to handle the many hazardous and corrosive chemicals on the market. A common drawback of these types of piping materials is the small amount of gasket load available before the flange is distorted or cracked. In 1989, Garlock responded to this problem by introducing ENVELON®, another member of the GYLON family.

ENVELON has a soft material on the gasket/flange interface where compressibility is important, but has a harder core in the middle to prevent media permeation and blowout.

High Pressure Service, Chemical Compatibility

As production demands increased, pipe hammering and/or pressure spikes became more common. GYLON Series HP 3560 and HP 3561 were designed to meet those extreme conditions. These perforated stainless steel-inserted GYLON gasket materials outperform any other gasketing available for high pressure service where chemical compatibility is a concern.

Low Bolt Load Sealing

In 1994, Garlock introduced GYLON Style 3545 for low bolt load applications. It is designed especially to seal pitted, warped or wavy flanges and many non-metallic flanges. Featuring soft, compressible outer layers and a rigid PTFE inner core, Style 3545 is ideal in situations where a rigid gasket is required, such as hard-to-reach piping systems, valves and flanges. The layers of rigid PTFE and microcellular PTFE are sandwiched together using the proprietary GYLON process, rather than adhesives, for longer gasket life. Style 3545 is so innovative, it received the 1995 Vaaler award from Chemical Processing magazine.

Unlimited Sizes and Dimensions

With growing concern over fugitive emissions, the traditional dovetailing method of creating larger sized gaskets no longer meets customer demands. In response, Garlock created the Welded GYLON process. Welded GYLON eliminates dovetail leak paths and allows the use of large gaskets without handling problems or premature blowout. Today, GYLON gaskets can be welded to any size or dimension... another breakthrough for Garlock gasketing!

Unparalleled Reliability and Service

Garlock GYLON gasketing materials have evolved over the years with a focus on quality to meet and exceed customer expectations. The use of Employee Involvement, Statistical Process Control, Vendor Assurance Programs, and a continuous improvement philosophy guarantees end users the highest quality products available.

Testing is performed regularly on all styles and thicknesses to ensure the consistency of Garlock quality in GYLON sheets.

Quality American-made products, 41 years of experience, on-time delivery and value-added service programs, all are reasons why the GYLON family of products has become such a major sealing component in industry today.

There is no doubt that demands will change in the future. But one thing is certain—Garlock will continue to answer those changes and demands with products that are innovative and timely. GYLON, a name you can trust and a complete family of products to choose from for your gasketing needs.

Want to take a deeper dive into your gasketing materials?