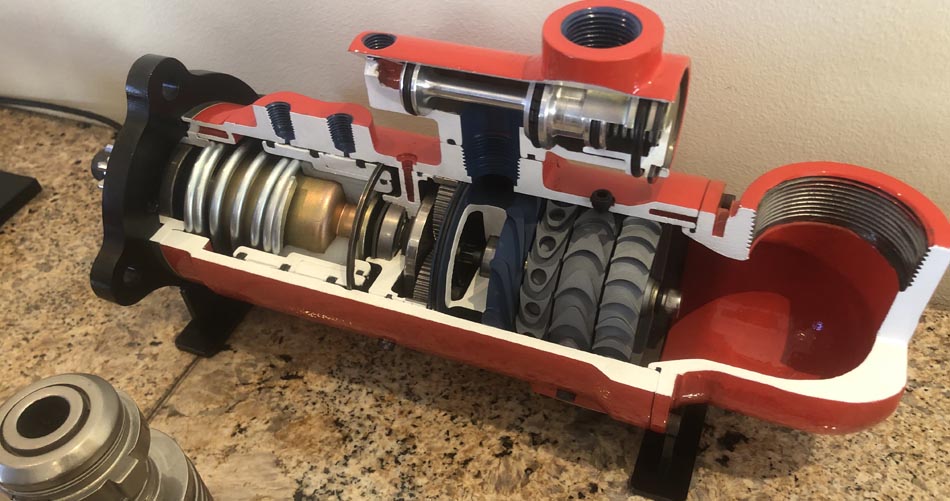

A 54%-per-component saving has been realised by Powerworks following the replacement of bronze bushings with a Vesconite low-friction bearings in the Jetstream turbine starters.

This is according to Powerworks Manufacturing Manager who was responsible for the initiative to replace the bushing located inside a drive spindle that acts as a guide for the spindle.

Testing for normal operation

The Manufacturing Manager noted that the saving has been achieved without any loss in performance, as attested to by six months of in-house testing on a Detroit 6-cylinder engine, a dynamometer, as well as on hydraulic test benches to test the efficiency of the motor.

Powerworks confirmed that the specific bushing was not subject to rotational wear in normal operation as it only moves backwards and forwards.

Vesconite was tested for this motion and no appreciable wear was measured, says a company representative.

Testing for rotational wear

The bushing was also tested for rotational wear to verify that it performed even in the unlikely situation in which the pinion gets stuck, does not disengage, and the starter begins to run together with the engine.

Since there are clutch teeth inside the housing, the latter scenario would result in the bushing running in the opposite direction to the shaft.

“We’ve tested it in house and we have run it in the opposite direction to see if there is an impact on it, which is not the standard application,” states the Manufacturing Manager, who noted that the testing confirmed that the bushing did not show wear even in the worst-case scenario.

On Powerworks and the introduction of the bushing

Since Powerworks is ISO 9001 accredited, an engineering change notification was compiled on all the items that were tested, as is required for ISO certification rules.

Powerworks has since introduced the Vesconite bushing as a standard component in its pre-engage starter motor, and had used it in 300 units by the end of May 2021.

The company manufactures the bushings in-house along with all other components for the 3000 rpm starter motor that has a three- to five-second starting cycle.

The original article was published by Vesconite and can be found on their website.

For more information about Vesconite and to see if it might be right for your application, contact GFS today.