A large beverage producer turned to Vesconite Bearings for a solution when it found that its forklift side-shift pads were not able to cope with the typical 2-t beverage loads that its single double-pallet-handler forklifts carried.

Side-shift pads are located between the forklift attachment and the carriage of the forklift, and allow the user to shift a load for quick and accurate placement by a stationary forklift onto a goods truck.

However, in the case of the beverage company, the originally-installed pads were quickly bitten into by the forklift attachment when moving the heavy beverage-containing pallets.

“The original nylon pads lasted about two weeks until they started being bitten in to, and then we had to use silicon spray,” says the company’s forklift technician.

Since forklifts are an integral part of the company’s business, which relies on efficient materials handling and logistics to supply large volumes of beverages, an intervention was needed.

Gallagher's partner, Vesconite, answered this requirement by supplying load pads in Vesconite Hilube, its proprietary engineered, self-lubricating, wear-resistant polymer.

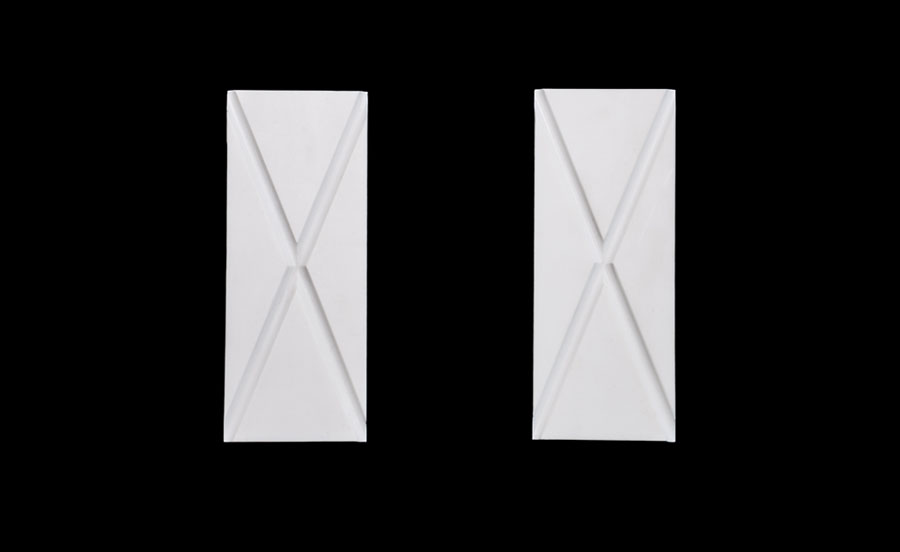

The bearing and wear material company supplied a modified pad design with smooth dirt-trapping grooves on the load-bearing side, which would allow a smooth side-shift motion on a self-lubricated surface while trapping environmental dirt and debris.

The design was further modified to have two larger fillets on the reverse side where the locating pins protrude from the pad to combat the stress concentration caused by the side-shift movement.

“Since then we haven’t had any problems with them,” informs the beverage company’s forklift technician, who notes that the side-shift pads have shown almost no wear between September 2019 and February 2020 – a more than 1000% improvement to date on the durability experienced in the past.

The beverage company has installed Vesconite Hilube side-shift pads on one operating unit’s factory forklifts and one of its other unit’s forklifts, in South Africa, and will roll out the polymer pads on its other South African distribution-hub forklifts.

The beverage company’s forklift technician notes that the forklifts operate at 80% weight capacity since its forklifts can handle 3-t load. The 2x pallet loads and attachment weigh 2.6 t in total.

The forklifts within the factory operate continuously, while the outside forklifts operate for 12-hour periods, from 6am to 6pm.

They are integral to the company’s supply of assorted beverages to South Africa as well as the broader African continent, to which some South African produced beverages are dispatched.

Since the Vesconite Hilube side-shift pads are working so well, the beverage company is also investigating other parts of the attachment in which grease-free Vesconite Hilube can be used, including the plain bearings on the shaft that extends the forks to create a double-pallet handler.

The company’s forklift technician reveals that the polymer will eliminate the use of grease on the forklifts, which will be desirable in a food-contact environment in which clients, besides wanting excellent quality beverages free of contaminants, also want to receive beverages in clean grease-free packaging from the international beverage company.

The original article can be found on Vesconite's website.

For more information about Vesconite, or to see if it's the right fit for your application, contact us today.