Often times gaskets for AWWA flanges are ordered as 150# or 300# ring or full face gaskets. Unfortunately, this can lead to customers receiving the wrong size gaskets. Not only are the flange dimensions different in some situations, but the dimensions for the gaskets may differ as well.

This blog will discuss the differences between ASME flanges and AWWA flanges and the gaskets associated with each.

ASME Flanges

ASME flanges are the most widely used and specified flanges throughout industry in North America. Flange sizes ½” through 24” fall under ASME B16.5 and flange sizes 26” through 60” fall under ASME B16.47. Within ASME B16.47 there are series A and series B flanges, with the noticeable differences in most cases being the bolt size and/or bolt quantity. Series A flanges typically have fewer, larger diameter bolts while Series B flanges typically have more, smaller diameter bolts. ASME B16.1 is another standard used in industry, and, while not as common as ASME B16.5 & B16.47, it does apply to cast iron flanges found on valves and pumps (i.e. 25#, 125#, 250#, etc.). As a side note, the drilling patterns for ASME B16.1 125# and 250# match up with ASME B16.5 and ASME B16.47 Series A 150# and 300# flanges up through 60” flange sizes.

AWWA Flanges

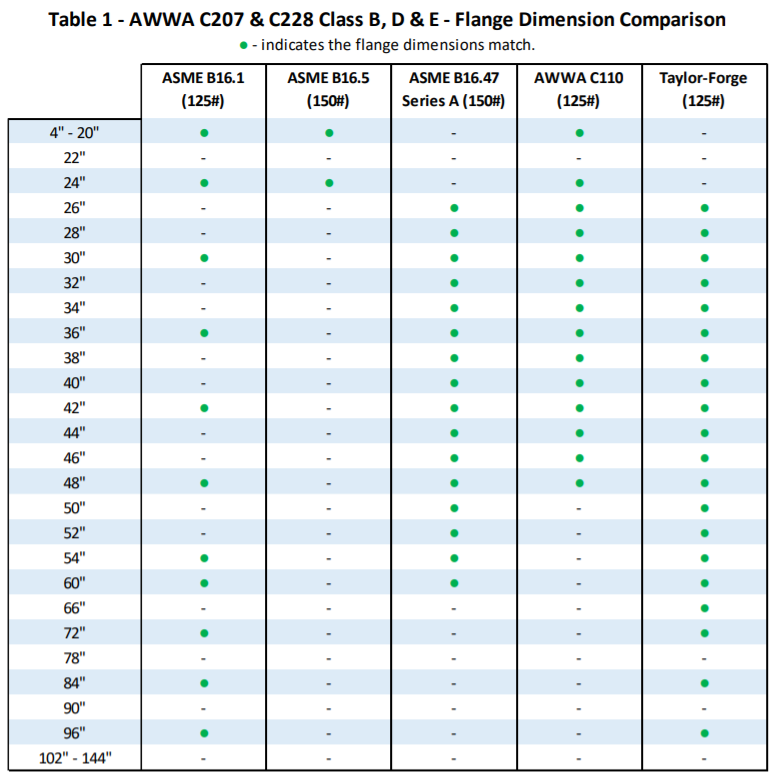

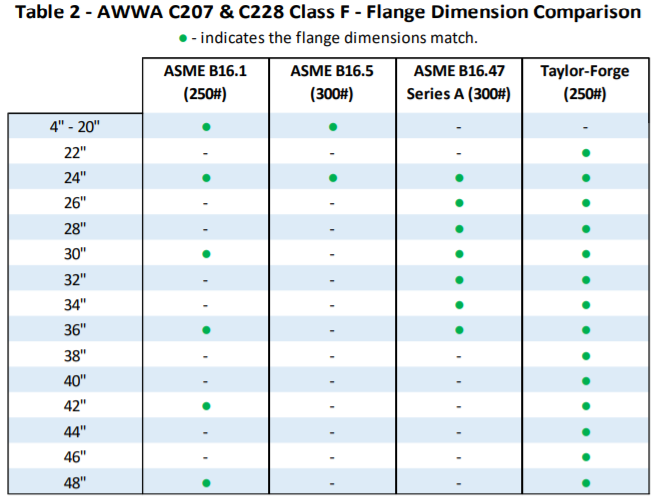

With water infrastructure piping systems American Water Works Association or AWWA standards are more common. For steel flange connections the standard is AWWA C207, which has four flange classes within it; Class B, D, E & F. While the dimensions for the AWWA C207 flanges do tend to follow suite with ASME 125#/150# and 250#/300# class flanges on many sizes, there are sizes where Taylor-Forge dimensions have been adopted, as well as larger flange sizes (above 96”) where the flange dimensions are unique to the AWWA C207 standard. Note that there are two other AWWA flange standards as well; AWWA C110 (ductile iron/gray iron flanges) and C228 (stainless steel flanges). These standards also tend to follow similar dimension rules as AWWA C207 (i.e. ASME B16.1, B16.5, B16.47, etc.). Table 1 and 2 provide a side-by-side comparison for reference.

The Confusion

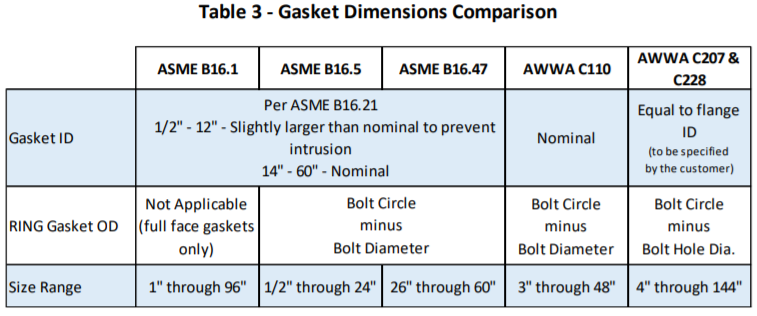

Gasket dimensions for ASME flanges are cut to the dimensions provided in ASME B16.21, which have a slightly larger ID for 12” and smaller flanges (to prevent gasket intrusion into the process stream), and RING gasket outer diameters are calculated by subtracting the bolt diameter from the bolt circle diameter of the flange. This method ensures when the ring gasket pushes the bolts to the outer edge of the bolt holes in the flanges for proper alignment/centering.

The AWWA C207 standard states the gasket ID dimension should be equal to the flange ID, which must be specified by the customer at the time of order. Also, the RING gasket outer diameter is calculated by subtracting the flange bolt hole diameter (NOT the bolt diameter) from the bolt circle diameter of the flange. This method allows for the use of electrical isolation sleeves over the bolts if cathodic protection is necessary. Table 3 below provides a comparison between the standards.

In conclusion, while these flange standards are very similar in terms of dimensions it is very important for customers to know what the differences are, and how to properly specify gaskets for the flanges in their respective systems.

>> Click here to see gaskets in stock and on-sale now <<

The original content was written by our partners at Garlock and can be found here.

For more information about gaskets or if you need a quote, please contact Gallagher Fluid Seals today.