The drive to reduce costs and environmental concerns have caused many design and processing engineers to turn to perfluoroelastomer sealing parts as the most cost-effective sealing solutions. The value-in-use of perfluoroelastomer can be proven in operating conditions where conventional elastomers fail. Even under less arduous conditions, DuPont Kalrez perfluoroelastomer seals can be the best solution, as they can last significantly longer than conventional sealing solutions.

Economics depend on the total system cost

When considering the economics of elastomeric seals, it is vital to look beyond the total cost related to the sealing solution. The total system cost in use is the sum of the cost of the O-ring seal plus the installation cost plus the downtime cost (including loss of productivity through leakage and clean-up costs).

Case studies show the value of high quality seals

The following case studies highlight the total system cost comparison. They take into consideration the frequency and cost of seal replacement as well as the attendant downtime cost.

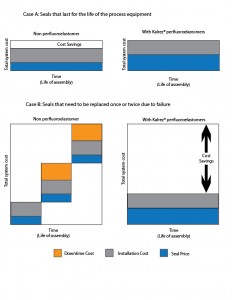

CASE A: Seals that last for the life of the process equipment

In this situation the seals are not being replaced, as they last for the life of the pump or the equipment. Strictly on a cost basis, perfluoroelastomers cannot be justified.

CASE B: Seals that need to be replaced once or twice due to failure

This is a situation in which seals need to be replaced for failure or maintenance reasons once or twice during the life of the equipment, introducing the added factor of downtime cost each time the seal is changed. Using DuPont Kalrez perfluoroelastomer seals could be the most cost-efficient solution.

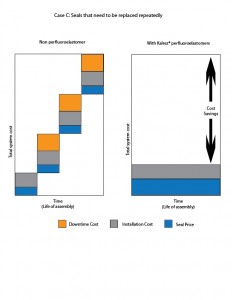

In this situation, seals need to be replaced several times. Using a conservative estimate of service life of perfluoroelastomer seals being four times that of conventional sealing material, the replacement and downtime costs associated with repeated, multiple replacements of existing seals far outweigh the initial higher costs for perfluoroelastomers. In addition, the unplanned replacement of existing seals would further increase downtime costs, as well as having other, possible serious, effects.

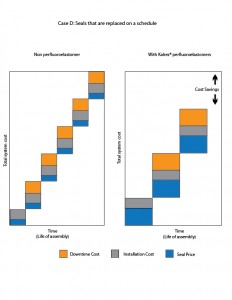

When seal are replaced on a regular basis rather than waiting for them to fail -- for reasons of safety, service, quality or economy -- the downtime costs incurred in replacing the existing seals are usually constant. The added expense of switching to DuPont Kalrez perfluoroelastomer seals should be offset by doubling periods between overhauls. In certain cases, this period could be tripled or quadrupled.

Examples of total system cost comparison

Manufacturing facilities continually strive to extend time between maintenance to reduce costly downtime. The example below shows costs related to a standard, cartridge, dual mechanical seal for the chemical process industry. Even with a relatively low 20 percent seal replacement rate over the lifetime of its assembly, savings could be realized from using DuPont Kalrez parts.

The second example below, on O-rings installed in couplings, shows that the lifetime of the O-ring has an even more dramatic impact on cost savings. Of course, each plant has its unique replacement rate and downtime cost. The chemical environment influencing the choice of the sealing material used must be considered when evaluating the potential savings from using DuPont Kalrez seals in an assembly.

Two field application examples

Application 1: O-ring seals fitted to product filling line, processing solvents, surfactants and concentrated herbicides at temperatures ranging from 10°C to 45°C, and pressures from 1.5 to 3.5 bars Eff.

Previous material used: Dynamic O-rings of PTFE

Average lifetime: One day

With DuPont Kalrez: Kalrez® Spectrum™ 6375 perfluoroelastomer O-rings extended the lifetime to an average of two months.

Application 2: Seals of fluoroelastomer (FEP/FKM), fitted to the piston rod of a type SRC Alfa Laval valve.

Problem/previous material used: Regular failure after only eight hour’s operation, lifetime of about eight hours.

With Kalrez perfluoroelastomer parts: Increase in operating lifetime from 8-12 months.

Overall advantages of choosing Kalrez

- Dramatic cost savings due to elimination of downtime

- Increased operating uptime

- Improved overall reliability of packing line

- Reduced maintenance

Example: Pumps with Mechanical Seals

| Non-FFKM | Kalrez | |

| Cost of O-rings (7 seals) | $28 | $700 |

| Cost of mechanical seal (repaired) | $750 | $750 |

| Installation Cost | $100 | $100 |

| Total Installed Cost | $878 | $7,550 |

| Number of pumps | $100 | $100 |

| Total installed cost | $87,800 | $155,000 |

| Downtime costs (average 2 hours)* | $6,000 | $6,000 |

Total System Cost – Example 1

| Non-FFKM | Kalrez | |

| Replacements per year | 20 | 8 |

| Replacement rate*** | 20% | 8% |

| Initial cost (seals and installation) | $87,800 | $155,000 |

| Replacement seal cost | $17,560 | $12,400 |

| Downtime cost | $120,000 | $48,000 |

| Total System Cost | $225,360 | $215,400 |

| Net Cost Savings | - | $9,960 |

| Cost Savings | - | 4% |

Total System Cost – Example 2

| Non-FFKM | Kalrez | |

| Replacements per year | 30 | 8 |

| Replacement rate*** | 30% | 8% |

| Initial cost (seals and installation) | $87,800 | $155,000 |

| Replacement seal cost | $17,560 | $12,400 |

| Downtime cost | $180,000 | $48,000 |

| Total System Cost | $294,140 | $215,400 |

| Net Cost Savings | - | $78,740 |

| Cost Savings | - | 27% |

Example: O-rings in couplings

| Non-FFKM | Kalrez® | |

| Cost of O-ring | $1 | $30 |

| Installation Cost | $100 | $100 |

| Total Installed Cost | $101 | $130 |

| Number of units used | 1 | 1 |

| Total installed cost | $101 | $130 |

| Downtime costs (average)** | $1,000 | $1,000 |

Total System Cost – Example 1

| Non-FFKM | Kalrez® | |

| Requested lifetime | 3 years | 3 years |

| Actual seal lifetime in example | 1.5 years | 3 years |

| Replacements during lifetime | 1 | 0 |

| Initial cost (seals and installation) | $101 | $130 |

| Replacement seal cost | $101 | $0 |

| Downtime cost | $1,000 | $0 |

| Total System Cost | $1,202 | $130 |

| Cost Savings | - | $1,072 |

| Cost Savings | - | 89% |

Total System Cost – Example 2

| Non-FFKM | Kalrez® | |

| Requested lifetime | 3 years | 3 years |

| Actual seal lifetime in example | 0.5 years | 3 years |

| Replacements during lifetime | 5 | 0 |

| Initial cost (seals and installation) | $101 | $130 |

| Replacement seal cost | $505 | 0 |

| Downtime cost | $5,000 | 0 |

| Total System Cost | $5,606 | $130 |

| Cost Savings | - | $5,476 |

| Cost Savings | - | 98% |

We hope this case study has been useful. We also want to take this opportunity to alert you to a special webinar next month, a joint effort of Gallagher Fluid Seals and Freudenberg.

This is your opportunity to learn more about Freudenberg Polyurethane Materials, and more specifically, the 94 AU 30000.

Gallagher will be hosting the webinar and will have Freudenberg experts available to you for questions during this event.

The webinar is scheduled for Thursday, December 3 at 10 a.m. EST, with a 15 minute question and answer session starting at 10:30 a.m.

*Downtime costs; without an in-line spare pump=$3,000 an hour, no downtime cost with an inline pump. Cost takes into account a pump going down, process shutting down, two hours to replace a seal, getting the process lined out and running again.

**Downtime cost of $1,000, 15-30 minutes to replace O-ring and rebuild coupling, or to install spare coupling.

***Average replacement rate based on case histories and real-life experience due to seal face, O-ring, maintenance and/or failure.