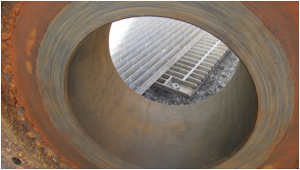

The gate was removed in September 2014 to perform inspection of gate wheel assembly and bearings. It was determined that several of the wheels had either stopped working or fallen off due to corrosion and lack of lubrication. The remaining bearings were found to have excessive clearance due to wear. New stainless steel sleeves were fabricated by Portland Manufacturing and welded onto the gate wheel stub shafts. New composite greaseless bushings supplied by CIP were installed to replace the failed bearings.

2015 Inspection

Tunnel gate was removed to inspect condition of CIP Composite Bushings. Wheels were removed to inspect and document condition of new stainless steel sleeves and CIP bushings. Sleeves and bushings were found to be in excellent condition and did not warrant further disassembly. Wheels were checked to make sure they were not bound up on the stainless steel sleeves and continue to rotate. All components look great after one year of service.

With excellent coefficients of friction, tested by Power Tech labs, CIP Composite material is ideal for locks and gates. The greaseless material is 100 non-metallic bearing material (no fiberglass or metallic shell) which allows for high edge loading and miaslignment capabilities. Successful applications include spillway gates, roller gates, intake gates, stop gates, bulkhead dates, sluiceway gates, weir gates, and navigation locks.

CIP Hydro™ is suggested for use in most hydro projects. It is manufactured with polyester and PTFE combined textile, along with high performance polyester resin and solid lubricants evenly dispersed through the material (eliminating the need for additional lubricants. Proprietary additives are included to increase the overall strength and reduce friction and wear.