One relatively new Parker product is their line of hygienic sanitary gaskets, coming out of the company's integrated sealing systems (ISS) Division in Lynchburg, VA. These compression controlled gaskets are used widely in the food processing and pharmaceutical industries, being USP Class VI, FDA, and NSF approved.

Here's what Parker has to say about these products:

Parker’s hygienic sanitary gaskets are patent pending designs which offer long-term sealability, excellent wear performance, complete material traceability and easy installation.

Our sanitary gaskets are designed to meet typical ASME-BPE hygienic clamp unions with a nearly flush interface (± .008”), preventing the entrapment of any media within a dead space that can lead to microbial growth and contamination. In addition, the flush interface helps prevent erosion of the elastomeric gasket that could contaminate the process stream. During the product development process, the sanitary gaskets were subject to extensive steam-in-place cycle testing – which validated their performance potential.

Product Features

- Inner seal beads provide primary point of sealing.

- Redesigned outer bed geometry maintains sealing capability.without an overfill condition that could cause the material to extrude into the ID during thermal expansion.

- Outer clips help to align gasket to the flange.

- Extended plastic on one inch and larger sizes helps support seal beads and maintain flush interface.

Benefits

- Intrusion/recess of the gasket less than .008”.

- Long-term sealability.

- Easy part alignment during installation.

- Material traceability back to the raw ingredients.

- Compression on the gasket is automatically controlled by plastic carrier.

- Easy part removal from the flange after use.

Laboratory Testing For Intrusion and Sealability

During product development, Parker’s sanitary gaskets were evaluated by an independent test laboratory. In doing so, Parker confirmed its products perform better than what exists in the market today.

Laboratory Test Details

Each cycle consisted of exposure to 130 °C saturated steam for one hour and 15 minutes of exposure to ambient room temperatures with ramp times in between. At the conclusion of 10, 100, and 500 steam-in-place (SIP) cycles, pressure tests were conducted with the use of riboflavin to better witness any compromise to seal integrity. Pressures were held at 3.1 bar and monitored for pressure loss.

All hygienic clamp unions were tightened to a torque of 3.38 Nm in order to provide consistency of results.

Test Results

After the completion of 500 SIP cycles, Parker’s gaskets exhibited an average of .003” of intrusion. The EPDM gaskets displayed:

- 93% intrusion/recess improvement over standard EPDM gaskets.

- 91% intrusion/recess improvement over PTFE/EPDM envelope gaskets.

- 92% intrusion/recess improvement over EPDM compression-controlled gaskets.

- The ability to hold pressure without having to re-torque the clamp, resulting in labor cost savings.

- The ability to disassemble the joint and remove the gasket by hand without the use of external tools, improving the

safe removal of the gasket and reducing labor costs.

Parker’s EPDM gaskets met the ASME-BPE intrusion/recess categories I (± .025”), and II (± .008”), and maintain seal integrity, as evidenced by the pressure tests through the duration of 500 SIP cycles.

Material Traceability

Each sanitary gasket has product identification etched on the part to allow for full traceability. The etched identification includes codes for the material type, manufacturing shift, and date. Parker’s internal rubber mixing capability ensures full traceability back to the raw ingredients used in production.

Product Offering

Parker’s hygienic sanitary gaskets are offered in our E3609-70 compound, a USP Class VI, FDA and NSF approved ethylene propylene (EPDM) material; as well as fluorocarbon (FKM) and silicone (VQM) materials.

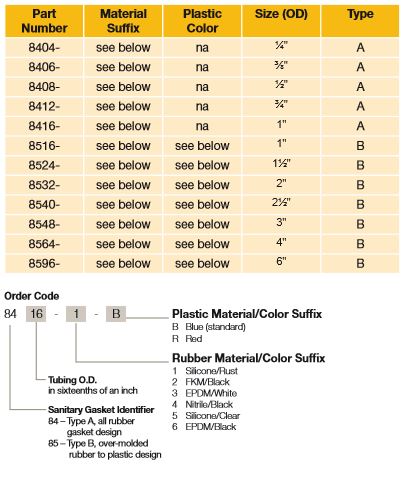

Hygenic Sanitary Gaskets