Knowing what counts: as the market specialist for demanding sealing applications in process industries, Freudenberg Process Seals has expanded its range of EPDM materials and optimized it for use in the most critical application scenarios, allowing us to offer you uncompromising functionality for smoothly running production processes in an even broader spectrum of applications.

Enhanced Temperature and Media Resistance

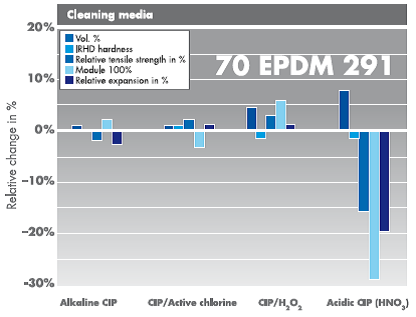

In comparison to conventional EPDM compounds, the new EPDM displays considerably higher water steam resistance, in addition to its exceptional durability in CIP/SIP media (Cleaning-in-Place/ Sterilization-in-Place). Depending on the individual application and design, Freudenberg’s EPDM is available in the following hardness ratings:

- 60 EPDM 290

- 70 EPDM 291

- 85 EPDM 292

Freudenberg recommends 70 EPDM 291 as the standard material, which can be employed e.g. as a reliable O-ring seal for static applications. This version can also be optimized for dynamic applications by means of a friction-reducing RFN™ coating.

Otherwise, the compound 85 EPDM 292 is the right choice for dynamic applications. Given its specific performance profile, 60 EPDM 290 is especially well-suited for use in diaphragms.

Outstanding Performance in Critical Media

| Water Steam | CIP / SIP Media | Ozone Resistance (40°C) |

| Up to 180°C (short-term to 210°) (a substantially higher resistance to water steam compared to other EPDM compounds) |

Very good resistance to nearly all conventional cleaning media. Cleaning at 82°C in CIP media and sterilization at 149°C is possible (3-A® Sanitary Standard Class II) |

At 1000 pphm, EPDM 291 and 292 offer the highest level of ozone resistance in comparison with other elastomers |

Certifications & Authorizations

Given its compliance with all essential national and international standards, EPDM materials can be universally employed nearly anywhere in the world. The materials are approved for use with a variety of drinking water standards and meet the requirements of the food and beverage and pharmaceutical industries.

Drinking Water Certifications

| Standard | Country | 60 EPDM 290 | 70 EPDM 291 | 85 EPDM 292 |

| NSF 61 | USA | X | X | X |

| WRAS | Great Britain | X | X | X |

| ACS | France | X | ||

| KTW | Germany | X | X | X |

| W270 | Germany | X | X | X |

| kiwa | The Netherlands | X | ||

| WQC | Australia | X |

Certifications for Food & Beverage and Pharmaceutical Production

| Standard | Country | 60 EPDM 290 | 70 EPDM 291 | 85 EPDM 292 |

| FDA | USA | X | X | X |

| EG 1935/2004 | Europe | X | X | X |

| 3-A® Sanitary Standards Class II | USA | X | X | X |

| USP Class VI | USA | X | X | |

| ADI free® | X | X | X |

Standard Commercial Dimensions

Normally, the following dimensions are in stock at Freudenberg Process Seals:

- Inch Sizes: ARP001 – ARP932

- Metric: ID 3mm – 193mm

- Thicknesses: 1.00mm – 8.00mm

- Other dimensions available upon request

Your Advantages at a Glance

- Materials compliant with national and international standards

- Very good resistance to water steam and CIP/SIP media

- Especially good heat resistance in water up to 180°C

- Available as O-rings, molded parts and diaphragms

- Clamp gaskets in accordance with DIN 32676

- Broad range of inch and metric O-ring sizes in stock