The basic purpose of an expansion joint is to absorb movement and vibration in a rigid piping system, being built to expand, contract, and adjust without straining or breaking the piping or ducting on either side. They are specially engineered to handle movements due to thermal expansion, vibrations of pumps, and misalignments due to installation tolerances, while also being resistant to the process conditions and the external influences of the application.

Types of Expansion Joints

- Fabric and rubber construction

- Reinforced with metal/wire rings

- Full-face flanges integral with joint body

- Flanges drilled to companion bolt pattern

- Gaskets not required

- Offset available

- Accommodates greater movement than single arch

- Minimum joint length depends on number of arches

- Maximum of four arches recommended to maintain lateral stability

Sleeve

-

- Slips over straight ends of open pipe

- Ends secured by suitable clamps

- Recommended for low pressure service only

Taper or Reducer

- Connects piping of different diameters

-

- Eccentric: axis of one end offset from other end

- Tapers in excess of 15˚ are not recommended

- Pressure ratings are based on larger I.D.

- Available with or without arches

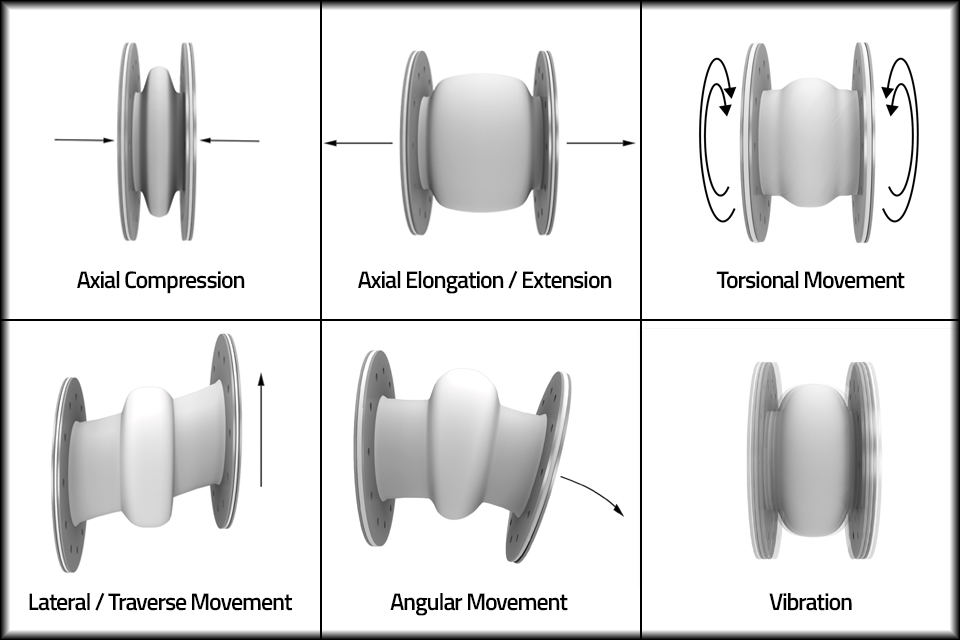

Types of Pipe Movement

Axial Compression

- Longitudinal movement shortens face-to-face dimension along axis of expansion joint or flexible coupling

- Pipe flanges remain perpendicular to axis

Axial Elongation / Extension

- Longitudinal movement lengthens face-to-face dimension along axis of expansion joint or flexible coupling

- Pipe flanges remain perpendicular to axis

Torsional Movement

- Rotation of one flange with stationary counterpart

- Simultaneous rotation of both flanges in opposing motion

Lateral / Traverse Movement

- Offset movement of one or both pipe flanges

- Both flanges remain parallel to each other while forming angle to axis of joint

Angular Movement

- Deflection or rotation of one or both flanges

- Forms angle with axis of expansion joint or flexible coupling

Vibration

- Oscillating movement around axis of expansion joint or flexible coupling

- Pipe flanges remain parallel with each other

- Flanges remain perpendicular to axis

- Mechanical vibration in steel piping system

For more information on elastomeric expansion joints, download our Expansion Joint Design Guide today! If you have questions about how to implement a robust preventative maintenance program for your expansion joints, including annual surveys including visual inspections and tagging, please do not hesitate to contact us.