GYLON EPIX™ is a family of gaskets that effectively seals a broader range of applications and is more forgiving during the installation process. It allows the end user to save valuable turn-around time, reduce re-work, and lower costs, helping them to finish ahead of schedule and under budget.

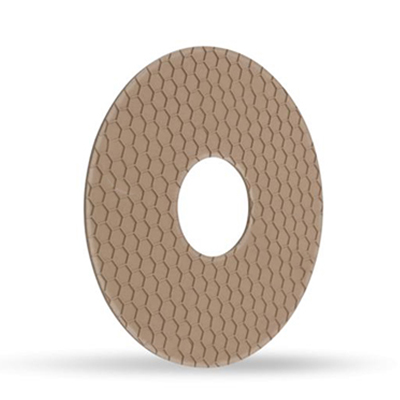

GYLON EPIX™ features a hexagonal surface profile that provides the torque retention and blowout resistance of a thin gasket and the conformability of a thicker gasket. GYLON EPIX® Style 3500 is a high performance, silica filled PTFE gasket sheet material designed for use with strong acids, solvents, hydrocarbons, and other aggressive media. GYLON EPIX® Style 3500 withstands a wide range of chemicals for extended service in a wide variety of applications.

INDUSTRY

Chemical

CUSTOMER

Manufacturer of chlorovinyl products

BACKGROUND ON APPLICATION

Expanded PTFE and 1/8” thick silica filled PTFE were formerly used to seal large diameter manway covers on FRP storage tanks and HCl absorber columns.

. To seal the crazed surface RTV or doping agent is used on the surface prior to gasket installation. After gasket installation the joint and surface treatment are checked for tightness with a pneumatic air test.

OPERATING CONDITIONS

- Temperature - 180°F (82°C)

- Media - hydrochloric gas, organic vapors and brine service

SOLUTION AND BENEFITS

After inspection and treatment of the crazed flanges, Garlock recommended installation of GYLON EPIX® 3500 which is designed for use with strong acids and aggressive media. Additionally, the raised profile improves sealability in low load applications such as FRP flanges. GYLON EPIX® 3500 has been successfully in service for over 18 months with no signs of leakage.

The original article was written by Garlock and can be found here.

Gallagher Fluid Seals is an authorized distributor for Garlock. For more information about selecting the right gasket, or if you need application assistance, contact Gallagher Fluid Seals today.