Versatile and easy-to-install, this 100% ePTFE sealing cord is a cost-effective solution for large steel flanges in general-use applications.

Joint Sealant, the first form-in-place gasket, was invented by Gore more than 40 years ago. It is a time-tested sealing solution for steel flanges with large diameters, rectangular or irregular shapes, and rough or pitted surfaces. When compressed, this soft, conformable cord forms a thin yet strong seal. It can also seal applications where available bolt loads are low.

Versatile GORE Joint Sealant is standard sealing material for many MRO (Maintenance, Repair and Operations) teams because it seals reliably – and because it’s easy and cost-effective to install. For most applications, just peel off the adhesive backing, apply to the surface, and overlap the ends.

GORE Joint Sealant

Versatile GORE Joint Sealant is standard sealing material for many MRO (Maintenance, Repair and Operations) teams because it seals reliably – and because it’s easy and cost-effective to install. For most applications, just peel off the adhesive backing, apply to the surface, and overlap the ends.

Performance

- Min Temperature (F) -452°

- Max Temperature (F) 600°

- Max Pressure (PSI) 870

Typical Applications

- Large/non-standard steel equipment flanges, such as tank manways, ductwork, and housing covers

- Processes using highly-aggressive media, such as chemical processing, pulp & paper, mining & minerals, semicon, and power gen

Features and Benefits

- Creates a reliable seal

- Gasket creation and gasket installation are faster and easier with GORE Joint Sealant

- Broad chemical resistance profile: Chemical resistance to all media pH 0–14, except molten alkali metals and elemental fluorine

- Made of 100% monoaxially expanded PTFE (ePTFE), using Gore’s expansion technology to create a high degree of fibrillation

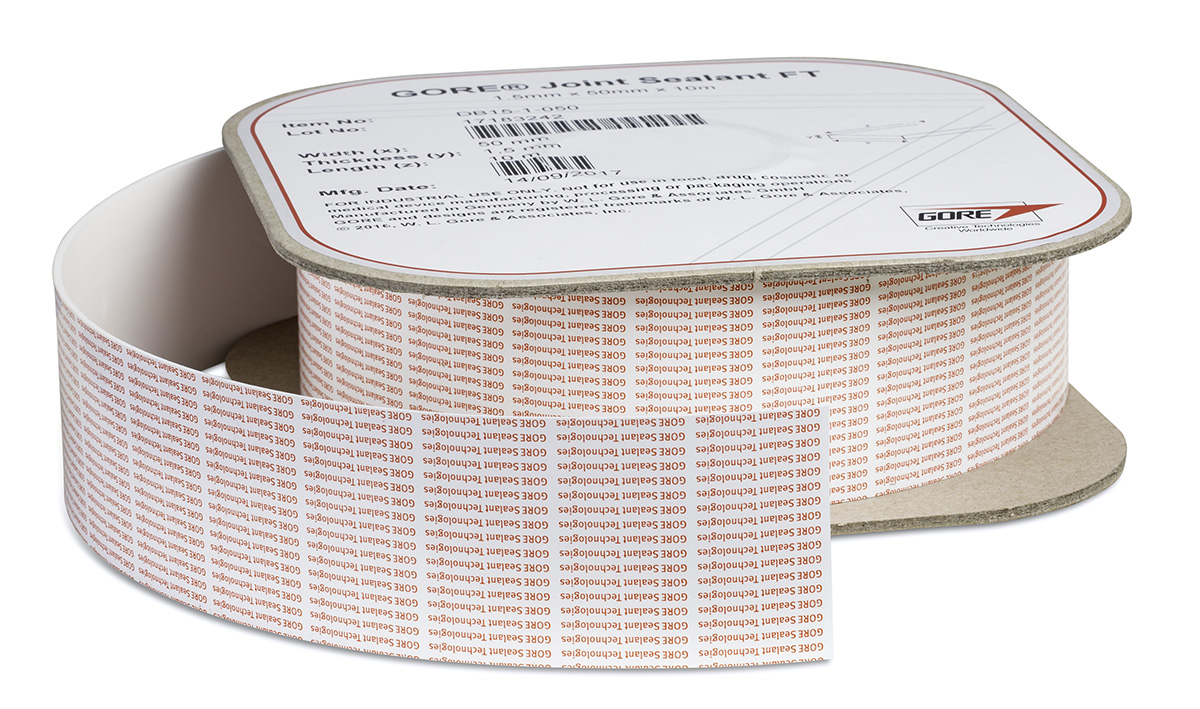

GORE Joint Sealant FT

Versatile GORE Joint Sealant is standard sealing material for many MRO (Maintenance, Repair and Operations) teams because it seals reliably – and because it’s easy and cost-effective to install. For most applications, just peel off the adhesive backing, apply to the surface, and overlap the ends.

Performance

- Min Temperature (F) -452°

- Max Temperature (F) 600°

- Max Pressure (PSI) 870

Typical Applications

- Large/non-standard steel equipment flanges, such as tank manways, ductwork, and housing covers

- Processes using highly-aggressive media, such as chemical processing, pulp & paper, mining & minerals, semicon, and power gen

Features and Benefits

- Creates a reliable seal

- Gasket creation and gasket installation are faster and easier with GORE Joint Sealant

- Broad chemical resistance profile: Chemical resistance to all media pH 0–14, except molten alkali metals and elemental fluorine

- Made of 100% monoaxially expanded PTFE (ePTFE), using Gore’s expansion technology to create a high degree of fibrillation

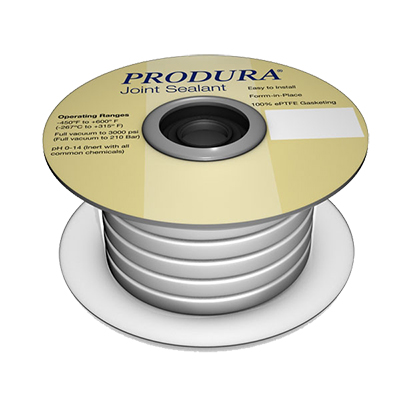

GORE Joint Sealant Produra

PRODURA joint sealant is a chemically inert cord sealant made with 100% expanded PTFE. It is an ideal form-in-place sealant for industrial gasketing users who wish to balance sealing reliability with cost.

Performance

- Min Temperature (F) -450°

- Max Temperature (F) 600°

- Max Pressure (PSI) 3000

Typical Applications

- Food and beverage

- Steam vessel flanges

- Heat exchangers

- Manhole covers

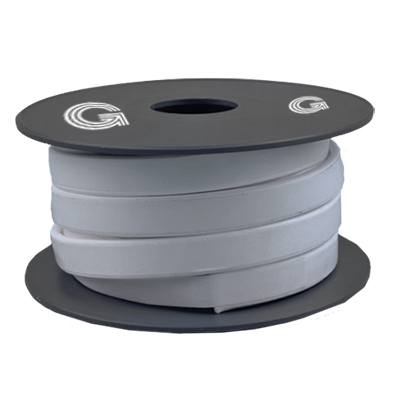

GFS Joint Sealant ePTFE

GFS ePTFE Joint Sealant is produced of 100% monoaxially virgin PTFE resins with one side adhesive. This Joint Sealant is a good sealing material for larger diameters of metal, rough, concave, and nonstandard flange shape surfaces.

Performance

- Min Temperature (F) -450°

- Max Temperature (F) 600°

- Max Pressure (PSI) 3000

Typical Applications

- Food and beverage

- Steam vessel flanges

- Heat exchangers

- Manhole covers

For more information, or if you need help with selecting the proper joint sealant for your application, contact GFS today.