Housing/Bore Considerations

Typical PTFE rotary lip seals are pressed into the bore to assure proper OD sealing and seal retention in the housing. Most seal and housings are made from steel and cast iron. Take care when softer materials – aluminum, bronze, plastic – are used for the housing. Aluminum has a thermal expansion rate almost double that of steel. Metal case designs can lose the required press fit in an aluminum housing when they go through thermal cycles due to the higher rate of thermal expansion of aluminum.

A finish range of 32 to 63 μin Ra (0.8 to 1.6 μin Ra) is recommended for service pressures up to 3 psi (0.20 bar). For thicker fluids such as grease, a 125 μin Ra (3.17 μin Ra) finish would be acceptable with no system pressure.

A lead in chamfer is strongly recommended for all seal housings. The chamfer aligns the seal during installation and helps keep the seal from cocking. Both corners of the chamfer should be free of burrs or sharp edges. For pressurized rotary applications, take additional precautions to ensure the seal isn’t pushed from the housing.

Pressure and Shaft Velocity

Seals that ride a rotating shaft have a contact point that is localized in one small area where dynamic forces and energy are concentrated. In fact, much of the energy from the shaft is dissipated at the seal through frictional heat and wear, both of which lower seal life.

This effect is exacerbated by an increase in shaft speed or perpendicular force holding the lip against the shaft. Shaft speed can be measured in surface feet per minute and the lip force can be approximated by measuring the differential pressure across the seal in psi.

Shaft velocity in surface feet per minute is calculated with these figures:

Shaft velocity (in sfpm) = Shaft diameter (inches) X Shaft RPM X 0.262

One way to estimate the exposure to these risks is to calculate the PV-value by multiplying the pressure held by the seal (P in psi) by the surface velocity of the shaft (V in surface feet per minute).

The product of the multiplication provides the designer with a guide to aid in the choice of seal profile and material.

The image below shows an example.

Shaft Misalignment and Runout

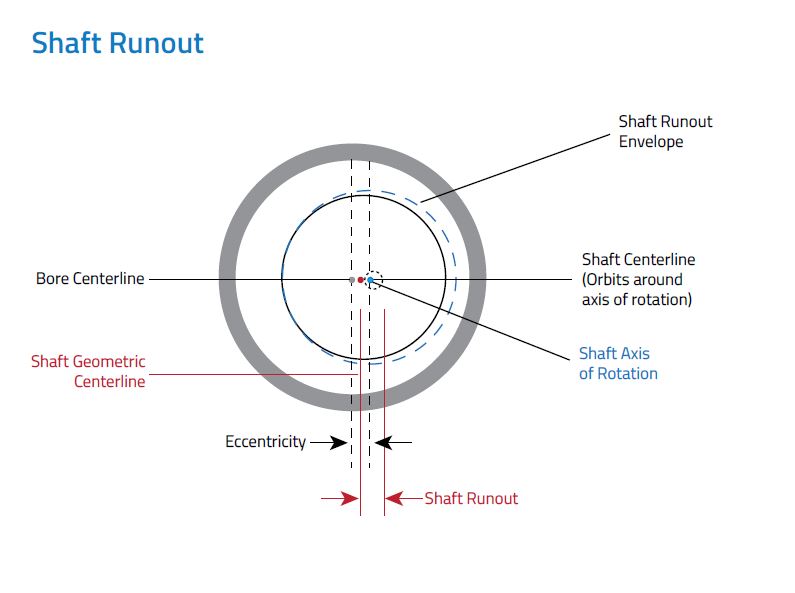

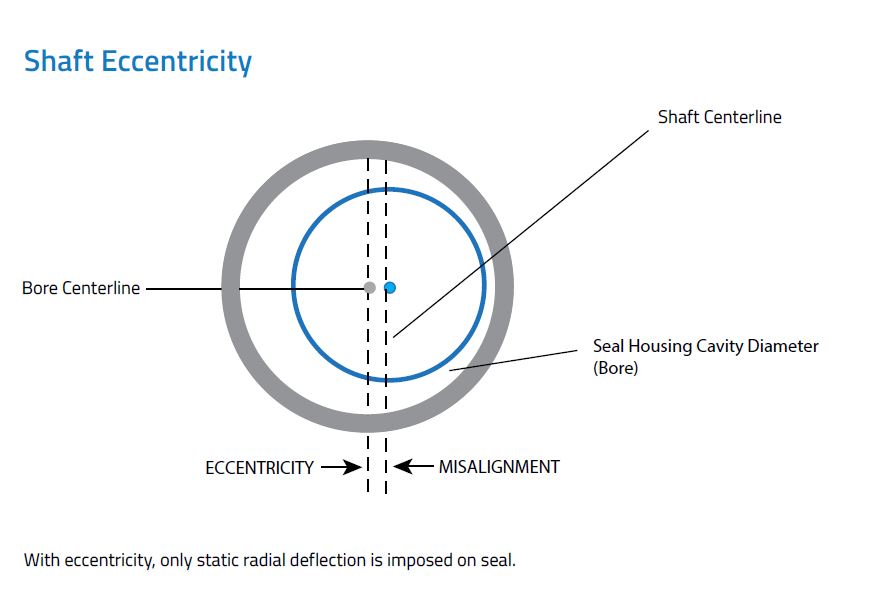

Applications with rotating shafts come with their own problems. Among these are misalignment, which occurs when the shaft isn’t aligned properly with the surrounding hardware. This manifests itself as eccentricity and runout. Eccentricity creates two problems. It forces the seal lip to follow a shaft that is not centered in the bore, wearing the lip more on one side. Because they are less elastic, PTFE seals are more susceptible to failure, misalignment and runout conditions than their elastomeric counterparts.

The second potential problem is that eccentricity enlarges the extrusion gap on one side, which could be detrimental if high pressure is involved.

Shaft runout is when the shaft is spinning on an axis of rotation that is offset from the geometric center of the shaft at the point of seal lip contact. Runout can be caused by a bent shaft or by whirling deflection while spinning. The seal must be sufficiently compliant to maintain contact with the shaft despite being compressed and extended each revolution. It follows that shaft runout becomes more of a problem at high speeds.

Every shaft has some degree of both runout and eccentricity, as shown in the figures below. All rotating shafts have some degree of runout and eccentricity. The risk of failure increases substantially if a system has a considerable amount of both.

In this case, cyclical radial deflection due to runout is superimposed on static radial deflection due to electricity.

With eccentricity, only static radial deflection is imposed on the seal.

Be sure to download Gallagher Fluid Seals’ rotary seal guide to learn more information about PTFE rotary seals and their