Tadpole Tape - Is it Right For Your Application?

Tadpole Tape Seals under light pressure while resisting flame and prolonged high temperatures

Tadpole tapes are resilient and nonabsorbent, flame-resistant gasketing materials. They are especially suited for applications requiring sealing under light pressure where bolting force is limited, such as doors, aircraft mounting rings, turbine flanges and combustion chamber inlets.

In service, sealing is accomplished by closure against the bulb of the tadpole. This specialized packing is constructed by wrapping heat resistant cores which form the “bulb” with a variety of specially treated cover materials. The edges of the covers are stitched or cemented together, forming the characteristic “tail” structure. Parker offers a variety of styles, materials and configurations in continuous coils and straight lengths.

Tadpole Tape Product Features:

- Ideal for sealing aircraft engine mounting rings, turbine flanges and combustion chamber inlets

- Effectively seals under light pressure, such as under light metal flanges where bolting force is limited

- Conforms to and easily seals uneven mating surfaces

- Will not harden when exposed to prolonged high temperatures

Which Tadpole Tape might be the right fit for your application?

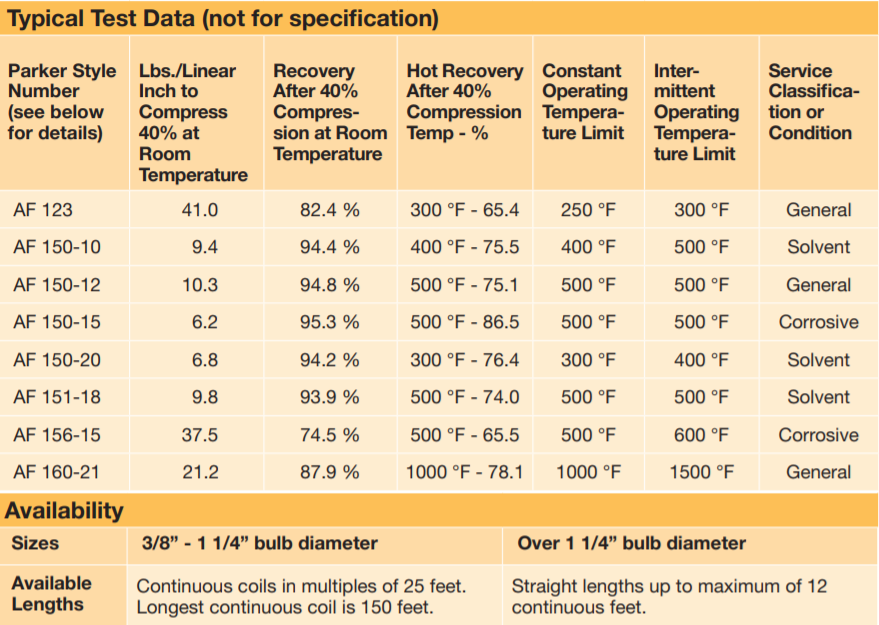

Style AF 123. Basic tadpole construction designed for steam service and constant temperatures to 250° F. It consists of a twisted fiberglass rope core and a cover of fiberglass cloth with brass wire

reinforcement. The cover is treated inside and outside with a compound containing natural and BUNA-S rubbers. The tail assembly is cemented.

Style AF 150-10. The most economically priced of the highly resilient, metal mesh core types. It consists of a knitted Inconel®* mesh core and a cover of fiberglass cloth with Inconel wire reinforcement. The cover is treated in side and outside with neoprene compound. The tail assembly is stitched.

Style AF 150-12. Offers high recoverability at constant temperatures to 500 °F. It consists of a knitted Inconel mesh core with a cover of fiberglass cloth reinforced with Inconel wire. The cover is treated with silicone rubber inside, and a flameproof neoprene base compound with aluminum finish outside. The tail is

stitched with fiberglass thread.

Style AF 150-15. Recommended where there is movement of the mating metal flanges. It consists of a knitted Inconel mesh core with a cover of fiberglass cloth. The cover is treated inside and outside

with PTFE suspensoid. The tail assembly is stitched.

Style AF 150-20. Lightest weight, easiest to compress, and has the highest recovery factor of all Tadpole tapes. It consists of a knitted Inconel mesh core with a cover of Inconel mesh. The cover is coated with neoprene cement on the inside and a neoprene compound on the outside. The tail assembly is cemented.

Style AF 151-18. Provides increased sealability with a foil wrapping over the core. It consists of a knitted Inconel mesh core wrapped with aluminum foil and a cover of fiberglass with inconel wire reinforcement. The cover is coated with neoprene cement inside and neoprene cement with an aluminum finish outside. The tail assembly is stitched.

Style AF 156-15. Treated with a PTFE suspensoid to reduce friction. It consists of a fiberglass twisted rope core, with a cover of fiberglass fabric, treated inside and out with a PTFE suspensoid. The tail structure is stitched.

Style AF 160-21. Withstands the highest operating temperatures of any Tadpole structure. It consists of a core of knitted inconel mesh and soft refractory fiber wrapped in aluminum foil. The cover material consists entirely of fine, braided Inconel wire. The tail assembly is stitched.

*Inconel® is a registered trademark of Huntington Alloys Corporation.

Gallagher Fluid Seals is an authorized distributor for Parker tadpole tapes. For more information or for application assistance, contact us today.