They are a top choice when the rubber-elastic quality of the seal is indispensable, but the application also requires better chemical resistance than traditional elastomers. The Gallagher Engineering Department can determine if an FEP-/PFA-encapsulated O-ring is right for your specific application.

In this blog post, our partners at Freudenberg Sealing Technologies outline some of the advantages of encapsulated O-rings.

FEP-/PFA-encapsulated O-rings consist of an elastomer core and a seamlessly closed casing of modified PTFE.

The elastomer core made of FKM (Viton) or VMQ (silicone) guarantees an even pretensioning at the sealing point. The seamless casing is composed of FEP (fluorinated ethylene propylene) or PFA (perfluoroalkoxy-copolymer). It ensures reliable sealing and high resistance to aggressive media. This produces performance similar to that of a PTFE material. Encapsulated O-rings are exclusively used in static applications since movement or abrasive media can destroy the casing.

For demanding applications involving aggressive media There are numerous applications where the use of traditional elastomers is ruled out. Aggressive chemicals or extreme temperatures can destroy conventional O-rings. This ultimately leads to leakage.

FEP-/PFA-encapsulated O-rings can be used wherever an elastomer’s chemical resistance is insufficient. Here FEP and PFA materials offer chemical resistance while the elastomer core provides elasticity. Seals made of PTFE are not an option in this case. The material does offer outstanding media resistance, but is not associated with elasticity.

What are the advantages to using encapsulated O-rings?

- Very good resistance to nearly all media (exceptions are alkali metals and some fluorine compounds)

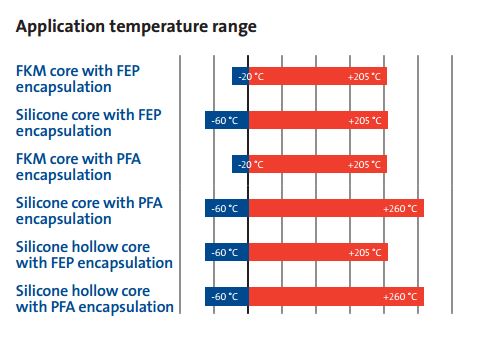

- Applications in broad range of temperatures

- Superbly suited for use in the food, chemical and pharmaceutical industries

- Low contamination

- Low permeation

- Low coefficient of friction prevents the stick-slip effect

- FDA-compliant

- Cost-effective, high-performance seal for many critical application areas

When should encapsulated O-rings not be used?

- In dynamic applications

- In contact with abrasive media

- Under high pressure

- When the O-rings are highly elongated

- When there are high press-in forces in the housing

Availability

Depending on the cross-section diameter, encapsulated O-rings have a lower limit to their inner diameter. If this is taken into account, practically any size can be manufactured.

Profiles and dimensions

The most used profile is the circular cross-section. Oval, rectangular and square profiles can be produced on request. Varying cross-sections are possible in both round and angular profiles. Since there are additional tooling costs for elaborate encapsulations, deviations involving small quantities are not always economical. Encapsulated O-rings can basically be offered in all the metric and imperial cross-section thicknesses.

Customer-specific solutions can also be realized without difficulty. Popular cross-section thicknesses in many dimensions can be delivered from inventory. This ensures the cost-effective and fast availability of what you need. The minimum manufacturing size of the inner diameter depends on the cross-section thickness of the O-ring. At a crosssection thickness of 1.5 mm, the smallest possible inner diameter works out to 5.3 mm. This is a special size for which a production period of 25 work days must be budgeted. Inner diameters of at least 16 mm at a cross-section thickness of 1.5 mm can be delivered as standard, mostly from inventory.

There are no limits on the maximum size of the inner diameter. Since encapsulated O-rings are only slightly extendable and compressible, the installation space must be oriented to these characteristics when diameters are small.

Tolerances for inner diameters

Encapsulated O-rings cannot be produced with the same tolerances as conventional O-rings. They can deform due to the varying rigidity of the casing and the core due to temperature effects. But they are manufactured in such a way that they remain in compliance with DIN 7715M2F.

Materials

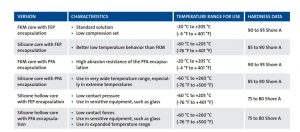

FKM or silicone is used as the material for the core of the encapsulated O-ring. EPDM is not recommended due to heat-related changes during the manufacturing process. FKM and silicone withstand these temperatures during production without a decline in performance.

FKM core – FKM (black) features very good rubber-elastic qualities. FKM has the capacity to re-assume its original form after its deformation thanks to its outstanding compression set.

Silicone core – The silicone core (mostly red) is considerably softer than an FKM core. In turn, it is more temperatureresistant. In addition to its superb thermal resistance, it has very good cold flexibility.

FEP encapsulation – FEP (fluorinated ethylene propylene) gives an O-ring its tremendous characteristics relating to its resistance to nearly all liquids, gases and chemicals. The exceptions are liquid alkali metals and some fluorine compounds.

PFA encapsulation – Perfluoroalkoxy copolymer (PFA) resembles FEP in its areas of application. It is distinguished by improved cold flow properties and optimized mechanical qualities at higher temperatures.

Approvals and compliance

- FDA-compliant

- USP Class VI

- EU Reg. 1935/2004

- 3-A® Sanitary Standards

- ADI-free

Characteristics

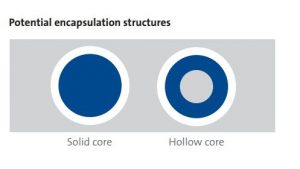

FEP and PFA are very similar in their characteristics. PFA stands out for its greater thermal resistance at temperatures exceeding 200 °C. Thanks to the opportunities for combining two encasing materials and two core materials, the best possible encapsulated ring can be selected for a particular application. The formation of the inner elastomer as a hollow core expands the range of applications to uses that require relatively low contact forces.

Advantages of FEP encapsulation

- High resistance to numerous chemicals

- High corrosion resistance

- Low compression set

- Low coefficient of friction

Advantages of PFA encapsulation

- All the benefits of FEP encapsulation

- Greater temperature resistance

- Greater mechanical strength

- Longer service life

- Greater cracking resistance