Baffle Seals Help Improve Heat Transfer

Shell-and-tube heat exchangers with removable tube bundles require that manufacturing clearances are present to facilitate the insertion and removal of the tube bundles for maintenance, repair or cleaning purposes.

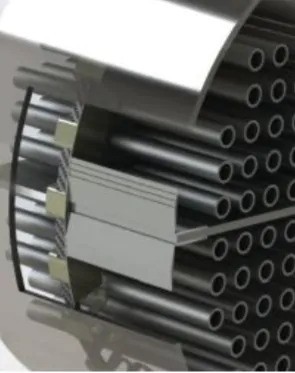

For heat exchangers designed for multipass flows within the shell — for example, Tubular Exchanger Manufacturers Association standard shell types F, G and H — it is common to incorporate a longitudinal baffle plate within the tube bundle design. These plates direct the shell fluid flow in desired directions to increase the dwell time of the fluid while in contact with the tubes, thereby increasing the heat transfer effectiveness of the exchanger.

Heat transfer efficiencies could increase by up to 10 percent using a baffle seal arrangement.

Due to the manufactured component clearances, repair operations, and possible wear and tear, there is often a substantial gap between the edge of the baffle plate and the inside diameter of the shell. This gap creates a natural path for the shell fluid flow to deviate from the intended flow direction, effectively shortening the dwell time in the exchanger and thereby decreasing heat transfer efficiency.

KLINGER manufactures and supplies a range of metallic baffle seals with leaf-like lamellae to effectively seal any gaps between the longitudinal baffle plate and the shell’s inside diameter. Virtually no bypassing occurs, and the shell fluid flow is forced to follow its intended directional path. The result is an increase in the heat transfer effectiveness of the exchanger.

Increases in thermal transfer efficiency result in reduced energy costs and ultimately provide operational cost savings. Depending on the gap dimensions and condition of the components, heat transfer efficiencies could increase by up to 10 percent using a baffle seal arrangement.

A different sealing design concept is applied to the gaps between any single segmental transverse baffle plates that may be present on tube bundles and the shell’s inside diameter. In this instance, a compressible wire mesh packing is used within a holder, which itself is wrapped around the outer circumference of the baffle plate to reduce and minimize any cross-baffle flow.

The seals are manufactured from German DIN 1.4571 material (stainless steel 316Ti) as a standard, but can also be provided in other material options based on specific process media conditions. The seals are fitted easily and under most circumstances require no additional tooling, drilling or bolting of the seal to the baffle plate.

Thermoseal Inc. is an expert in and leading manufacturer of fluid sealing materials and fluid control products. The company carries a range of baffle seals at its Houston location to fit the most commonly encountered baffle plate thicknesses, from one-quarter of an inch to three-quarters of an inch. Other sizes are also available on a make-to-order basis. The seals are supplied in pairs and cut to the exact length required for any specific heat exchanger application.

For more information, contact Gallagher Fluid Seals. We are an authorized distributor for Thermoseal and can provide engineering application expertise.