As the operating parameters of industrial technologies and manufacturing processes get more extreme, the need for optimal sealing solutions become that much more important.

Elevated temperatures and pressures, higher speeds, extreme environments, faster gas decompression, and aggressive medias all make sealing more critical. This extends right across static, reciprocating, rotary, and oscillating applications.

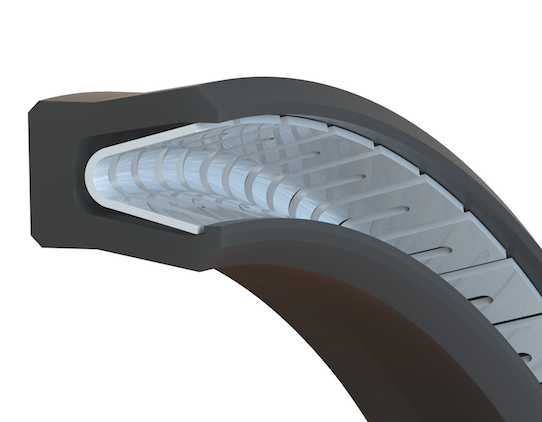

This challenge has been met very effectively by the inventive addition of energizers to seals. Energized seals give the ultimate performance in the most demanding conditions and critical applications.

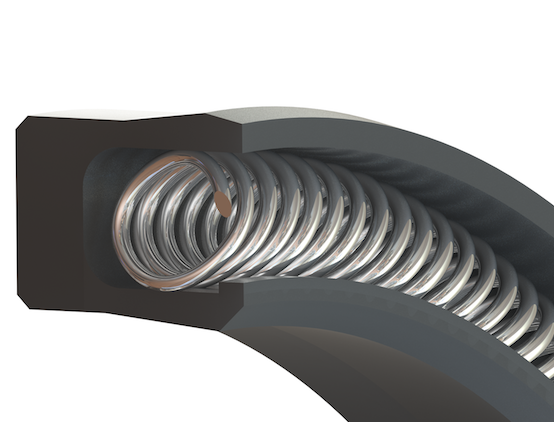

Spring or o-ring energizers can extend the normal limits of PTFE and plastic materials to deliver durable ultra-tight sealing capability. Here’s a rundown of how energizers work and how they can elevate your next sealing challenge.

How Energizers Work

PTFE has highly effective physical characteristics for seals, including low friction, heat tolerance, and chemical inertness. However, PTFE also has limited flexibility and elasticity.

Benefits of Energizers

The resilient pressure of an energizer compensates for and overcomes several practical problems, including the following:

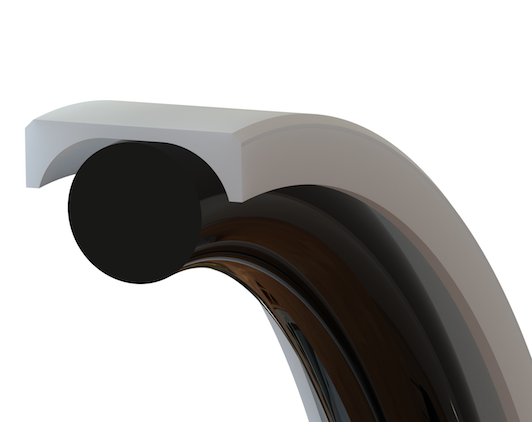

Lip pressure

Even after the lip material wears down over time, the energizer continues to push the lip tightly – otherwise the seal would become loose and leaky.

Adaption to deformation

With deformation of metal components contacting a seal (rods, shafts, cylinders, housings), energized lips adaptably fit around ‘humps and hollows’ to maintain sealing.

Adaption to misalignment

When components are misaligned, such as with eccentric deflection, energized lips dynamically move in and out to maintain close contact.

Picking up the slack

Manufacturing tolerances and clearances are not critical, as energized lips can ‘take up the slack.’ Thermal expansion and contraction can be likewise accommodated

Optimal Performance at All Pressures

The radial pressure maintained by a spring or o-ring keeps sealing lips in contact with mating surfaces even before fluid or gas pressure is applied, providing good low pressure sealing capability.

When system pressure is applied, energizer action is intensified – increasing the force on lips to make a tighter seal. The radial pressure is always higher than the pressure of the fluid or gas to be sealed.

The original article was written by Cliff Goldstein at Eclipse Engineering. It can be found on the Eclipse website.

For more information about energizers and if they are right for your application, contact Gallagher Fluid Seals today.